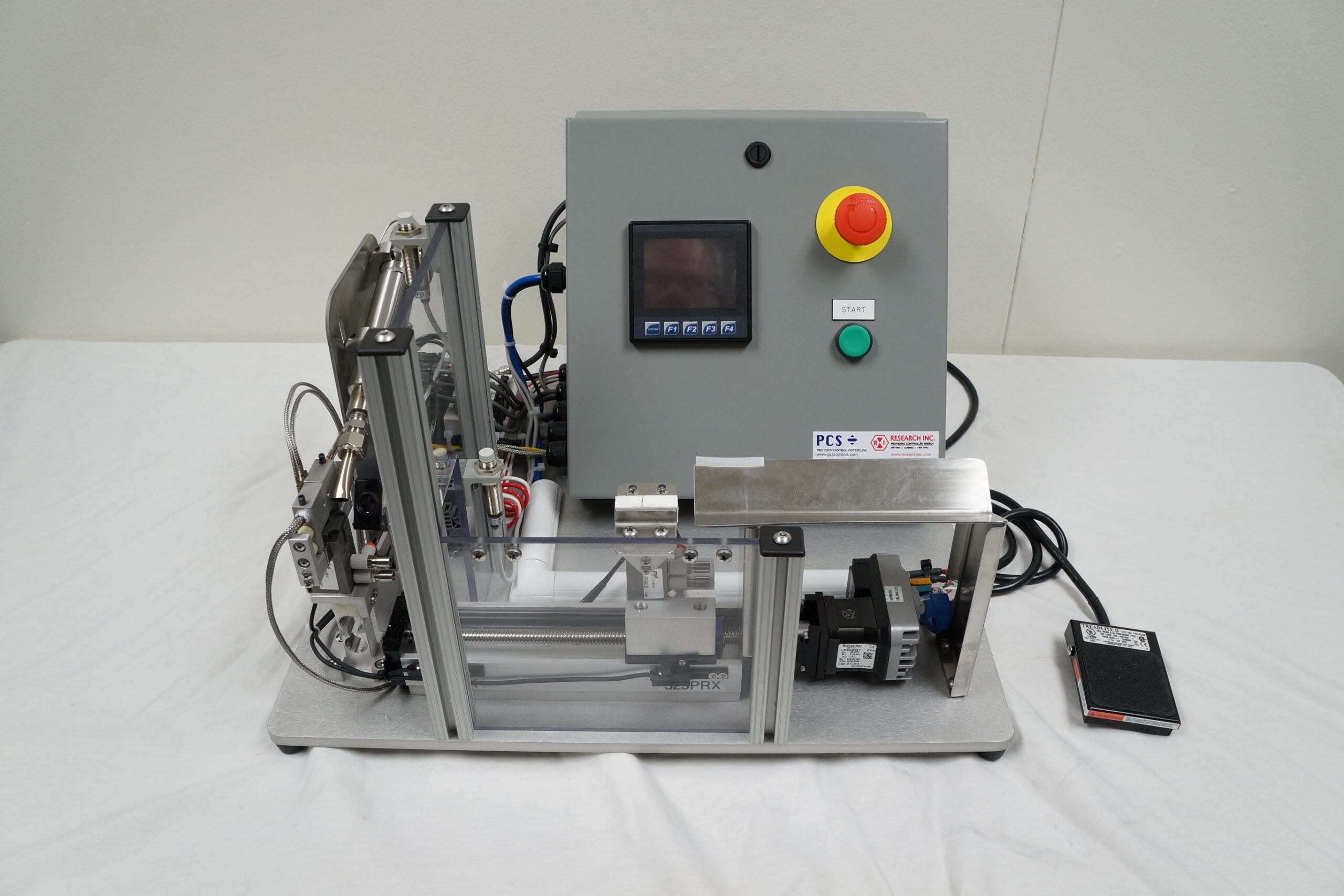

Medical Applications

At Precision Control Systems, we provide full in house engineering and manufacturing support to take your concept from initial design through final commissioning. Our team includes mechanical, electrical, and software engineers ready to develop custom systems that meet your performance, compliance, and production needs.

All systems are designed, built, and tested in our UL508A shop, ensuring consistent quality and integration.

Engineering Resources Available:

- COMSOL Multiphysics for heat transfer modeling and system optimization

- SolidWorks CAD and simulation tools for mechanical design and stress analysis

- AutoCAD Electrical for detailed electrical schematics and panel layouts

- Bambu 3D printer for rapid prototyping and iterative fixture development

- On-site test lab for concept validation, prototyping, and thermal process trials

System Support & Service Contracts

We are committed to long term support of the equipment we build. Each system includes free remote troubleshooting for the life of the equipment, along with a 1 year standard warranty.

For extended support, we offer customizable service contracts, which may include:

- Scheduled preventative maintenance visits

- Guaranteed emergency onsite response

- Spare parts stocking agreements with discounted pricing

- Software/Firmware updates